Case sharing - automated warehouse solutions in chemical industry

Chemical industry is the basic and pillar industry of the country. Its development speed and scale affect all aspects of social economy. With the rapid development of Chinese society, higher requirements are also put forward for the chemical industry. Technology and ecology are driven together, and intelligent logistics warehousing has gradually become the just need for the survival and development of manufacturing enterprises.

The chemical industry has a variety of products and high output, but due to the production process, there is a common smell problem, the storage environment of the operation is not pleasant, and there are problems of difficult recruitment and high labor cost all year round. Moreover, the chemical industry has a large demand for storage area, and the traditional warehouse capacity is developed horizontally. In a city with an inch of land is an inch of gold, the land purchase cost and labor cost are undoubtedly a great challenge on the development road of the chemical industry.

The application of automated three-dimensional warehouse in the chemical industry contributes to the intelligent upgrading of warehousing and logistics, improves work efficiency, reduces management cost, and realizes the optimization and improvement of enterprise production. It is an indispensable part of modern logistics warehousing.

#Automated warehousing solutions#

Lisen Automation automated storage division specializes in providing one-stop intelligent logistics storage solutions, making full use of storage space and effective area, and realizing equipment network control through software technology, so as to process goods and data output efficiently, centrally and stereoscopically. Lisen Automation intelligent storage series products include: roadway stacker, light / heavy stacker, conveyor, shuttle vechicle, three-dimensional warehouse management system, AGV, etc. Automatic access, first in and first out, all-round upgrading of modern enterprise warehouse management.

Application case

Qingyuan Wanma New Material Co., Ltd. is an enterprise specializing in the R & D, production and sales of high polymer materials for wires and cables - cable insulation materials. Due to the variety of finished products (cable materials) and different packaging forms, there are storage problems such as high labor cost and low operation efficiency.

Lisen Automation provides customers with an overall solution for intelligent warehousing and logistics suitable for the chemical industry, integrates a variety of Lisen products: stacker, RGV, automatic pallet stacking machine, etc., realizes the interconnection of MES, ERP and other software with warehouse WMS, effectively solves customer key points and realizes the upgrading of factory automation. At present, the scheme has been completed and is in normal operation.

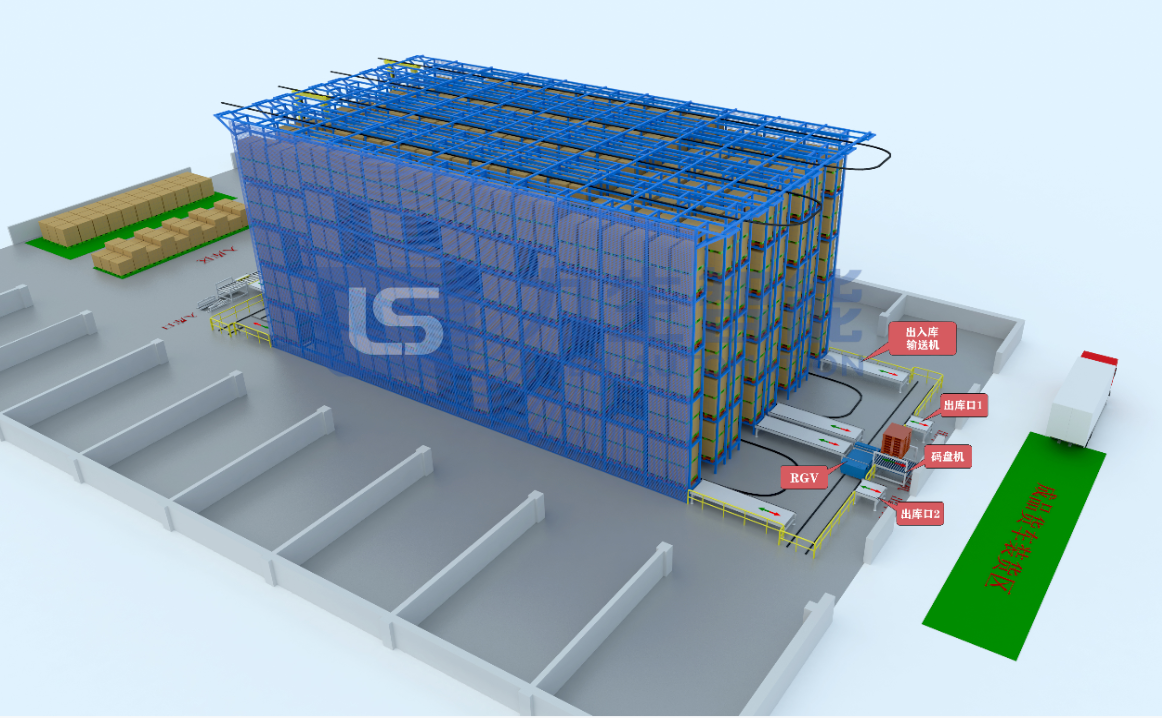

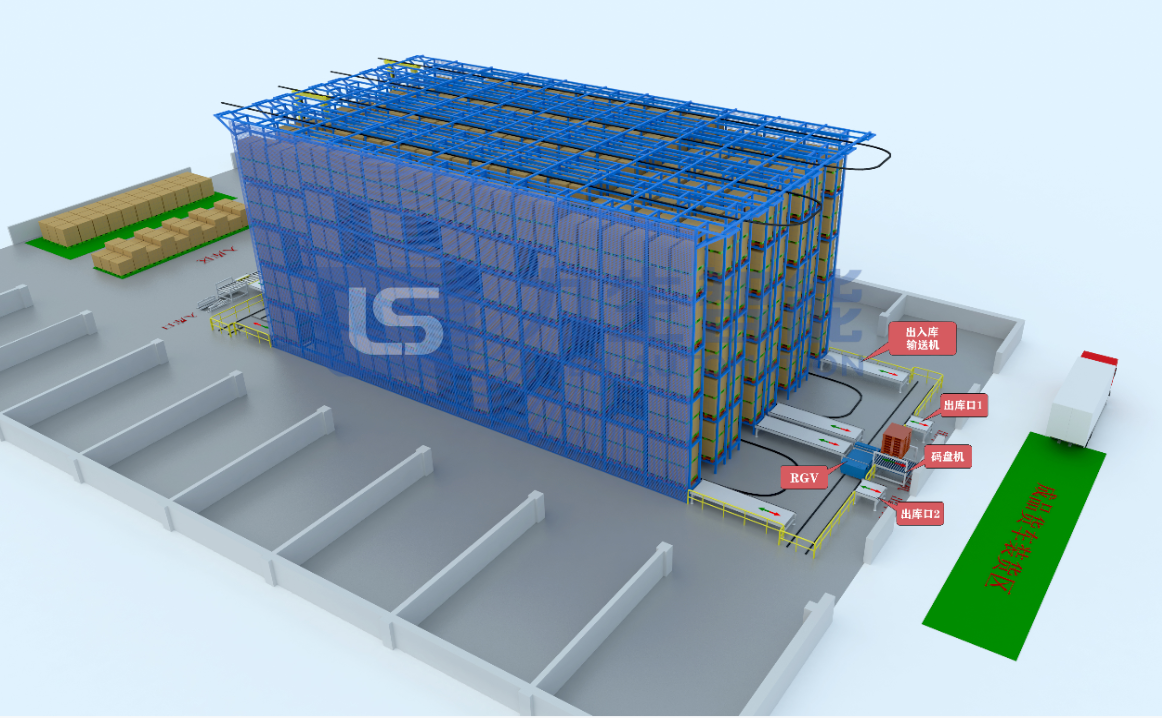

Inbound area

Fork elevator and roller elevator cooperate with the goods to arrive at the inbound area. The inbound conveyor and RGV trolley automatically store the goods in a regular manner. At the same time, the inbound port is equipped with a depalletizer , and the mother pallet is automatically supplied.

Shelf area

According to different packaging forms of products, create multiple cargo spaces with different cargo specifications, and adopt heavy-duty turning stacker equipment, with strong bearing capacity and load up to 2 tons, so as to quickly realize the storage of goods.

Outbound area

Two delivery ports are equipped with automatic pallet stack machine, multiple sets of delivery conveyors and RGV trolley to jointly complete the automatic transportation of products. The automatic pallet stack machine realizes the pallets stack operations of different specifications and shapes without manual alignment, improves the accuracy and reduces manual operations, thus saving time and labor cost.

Program highlights

1 High level storage improves utilization

Compared with the traditional warehouse, the automatic three-dimensional warehouse has a vertical expansion of storage capacity and makes full use of high-rise space. The maximum operable height is 40m, and the storage capacity is doubled, which effectively improves the utilization of storage space.

2. Accurate data , Comprehensive control of management

Realize the seamless connection between Warehouse Management System( WMS) and manufacturing system (MES), and the inbound and outbound are automatically scanned by computer; Automatic pick-up by stacker and automatic handling by RGV trolley, which is easy to avoid accidents and cargo damage, and the data accuracy can reach 99.9%; First in first out, online update, timely and convenient, and effectively realize the all-round control of people, goods, vehicles and equipment.

3. Multi vehicle assistance for safer operation

Through the systematic traffic control, the interactive operation and multi vehicle cooperation of various models such as elevator, stacker, forklift and RGV trolley are realized, forming a fully automatic and unmanned transportation process, which is safer and smoother, and greatly improves the automation level of the enterprise.

4. Full automation and low labor cost

The higher the degree of automation of warehouse management, the less the demand for traditional labor. The automatic three-dimensional warehouse solves the problems of difficult recruitment and high employment cost in the chemical industry with one stone, and creates a fully automated product warehousing process, which can reduce the labor cost by 80%.

In addition to the chemical industry, the automatic three-dimensional warehouse has a wide range of applications, as well as FMCG industry, automobile industry, electronic and electrical industry, machinery manufacturing industry, military industry and so on. Lisen Automation has been deeply engaged in automatic warehousing for many years and has provided services to many industry customers. The scheme technology is mature, the equipment is standardized, the service speed is fast and the cost performance is high. It not only brings considerable economic benefits to customers, but also helps enterprises realize the intelligence, informatization and automation of logistics warehousing management.

Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  中文

中文