Ⅰ. What is an automated warehouse?

An automated warehouse is also called an automated high-bay warehouse or active storage. It is a high-end rack-mounted warehouse system that uses computers for control, processing, storage, and retrieval.

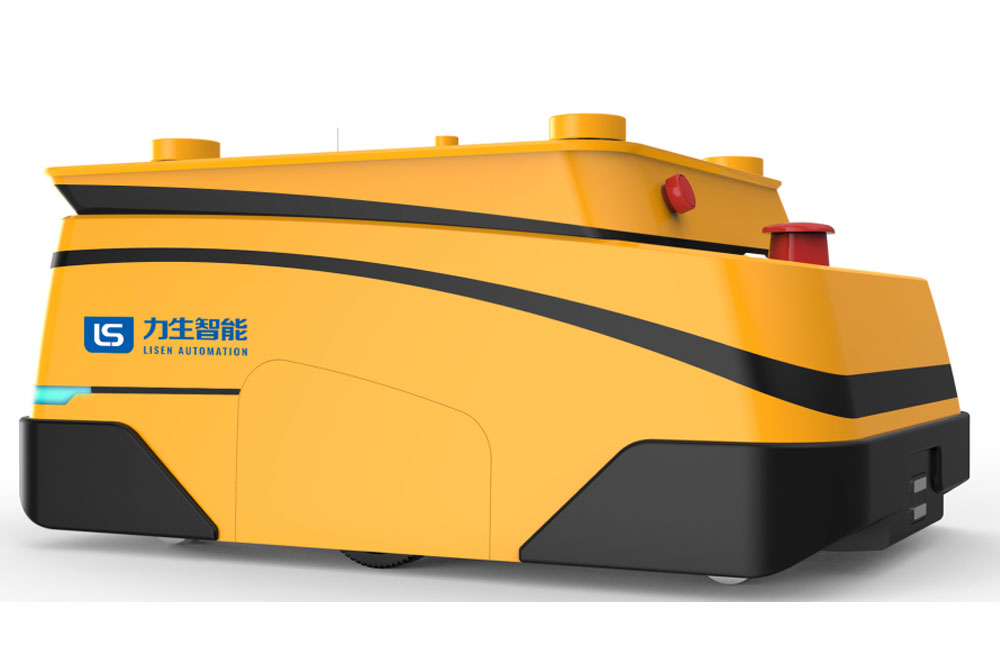

Automated 3D warehouses with automatic search for transportation equipment are essential for terminating high-energy transportation and large-capacity storage and playing a role that has nothing to do with modern manufacturing and product turnover. The automated three-dimensional warehouse is the completion stage of the open shelf storage system worldwide, combined with an automated sorting system and an automated guided vehicle, and is known as the three key signs of the modernization of logistics skills.

Ⅱ. What are the advantages of automated warehouses?

1. Since the automated warehouse uses high-level shelves to store products, it can open up larger storage space and make full use of the warehouse floor and floor space, thereby saving floor inventory and improving space utilization.

Now, the height of the world's tallest three-dimensional warehouse has reached 50 meters, and the unit area and capacity of the three-dimensional warehouse are 5-10 times that of conventional warehouses. The high-level shelf storage is combined with the computer management system to make the entry and exit of products more convenient, which will prevent natural aging, deterioration, rust, or mold of the goods.

2. Automated warehouse can realize active access. The use of machines and automation equipment can improve the efficiency of operation, increase labor productivity and reduce the labor intensity of operators. At the same time, automated warehouses can easily classify enterprise logistics systems, making enterprise logistics more reasonable.

3. Computer control can accurately store and process various information at any time, thereby reducing errors in product processing and data processing. At the same time, with the help of computers, the automated warehouse management system can effectively use warehouse storage functions to process inventory, reduce inventory reasonably, accelerate capital turnover, and save working capital, thereby improving the processing level of the warehouse.

4. The information system of the automated warehouse can be connected to the enterprise's production information system to terminate the enterprise's data processing plan. At the same time, because the automated storage solution can promote the privatization of enterprise science, it helps to reduce waste and achieve production balance. Therefore, the quality of operators and the level of processing personnel have also been improved.

5. The three-dimensional warehouse can produce great social and economic benefits to the company, and it can also enhance the company's image. In addition, the automated warehouse system is suitable for establishing a warehouse network to coordinate regional and nationwide logistics.

Automated warehouses are conducive to the establishment and implementation of a national standard system for product and material storage. These systems include general warehouse transaction process standards, general file format systems, processing departments, and operating standards. Automated warehousing is conducive to electronic processing in warehouses and mining companies, material storage at warehouse nodes, open distribution, e-commerce, and logistics. Automated warehouses can promote business opening and customer development, enhance operating methods, and strengthen the competitiveness of the organization.

Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  中文

中文