1. Sliding block sorting system

The sliding block sorting system is composed of a chain conveyor and a uniquely shaped sliding block, and a push block that slides left and right between the link plates for products sorting.

The body is 110 meters long, but due to the small gap between the products required for sorting, the sliding block automated sorting machine has many exits, and it can also be sorted to the left and right. It is very gentle in the sorting process and violent sorting is avoided, and sorting can be completed accurately.

2. Oblique guide wheel automated sorting machine

The oblique guide wheel sorting machine is an auto sorting system widely used in logistics centers in the United States and Japan after World War II. When the rotating oblique guide wheel goes up and down in the gap between the main narrow belts arranged in parallel, the sorting purpose of the goods is achieved.

The oblique guide wheel sorting machine can accurately find the location of the goods to be out of the warehouse from the huge high-level shelf storage system in the shortest time, and then deliver goods out of the warehouse according to the required quantity, and take out goods of different quantities from different storage positions. Then commodities are delivered to different tally areas according to different delivery locations, or centralized in delivery platforms for loading and delivery. The oblique guide wheel automated sorting machine has very little impulse to the goods during sorting, and the speed and accuracy are very high.

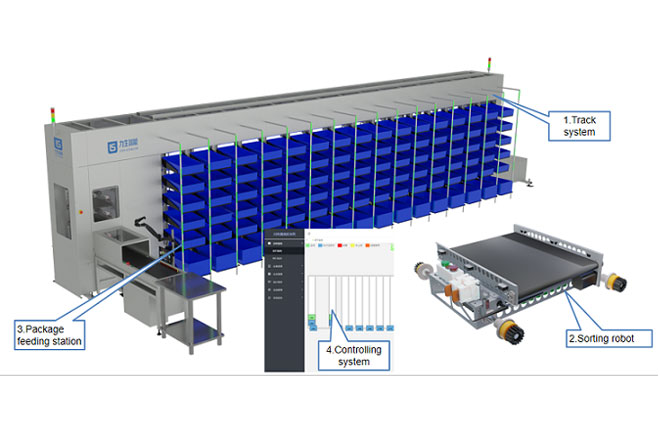

3. Crossbelt sorting system

The crossbelt sorting system is connected by a main drive belt conveyor and a trolley carrying a small belt conveyor ("trolley" for short). When the "trolley" moves to the specified sorting position, the belt is rotated to complete the task of sorting and sending out the goods, because the main drive belt conveyor crosses with the belt conveyor on the "trolley".

According to the specific conditions of the working site, it can be divided into horizontal circulation type or straight circulation type. The sorting capacity of this crossbelt sorter is very high, which can sort 6000 to 7700 items per hour, and is very suitable for airport baggage sorting and security inspection.

4. Tilt tray automated sorting machine

The sorting operation of the tilt tray sorter basically can be realized by an unmanned auto sorting system. The sorting capacity of the sorter is very strong. It places the sorted items on a steel belt or link plate conveyor. When goods arrive at the sorting site, the rocker arm rotates, and the goods slide along the inclined surface of the rocker arm to the destination. Moreover, the error rate is very low. The sorting error rate mainly depends on the accuracy of the input sorting information, which in turn depends on the input mechanism of sorting information. If the manual keyboard or voice recognition method is used for input, the error rate is 3% or more, while if barcode scanning is adopted for input, unless there is an error in the printing of the barcode itself, there will be no error.

Therefore, the current rocker-type automated sorting machine mainly uses barcode technology to identify goods. Not only that, the rocker-type sorter can sort goods continuously and in large quantities without being restricted by weather, time, human physical strength, etc. At the same time, because the rocker-type sorter has a large number of pieces sorted per unit time, the sorting capacity of the rocker-type sorter enables it to run continuously for more than 100 hours, and to sort 7000 packages per hour.

Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  中文

中文