Parameter of roller conveyor

Products | Light roller conveyor | Heavy roller conveyor |

Conveying mode | Roller | Roller |

Rated load | 50kg | 1000kg |

Driving mode | Electric roller | Motor |

Conveying speed | 20m/min | 12m/min |

Transmission mode | V-ribbed belt | Chain |

Power Supply | 3 phase 380V 50HZ | 3 phase 380V 50HZ |

Light roller conveyor

Heavy roller conveyor

Product features

Easy connection and transition between roller conveyors;

The roller conveyor has the advantages of simple structure, high reliability and convenient use and maintenance;

The utility model has the advantages of large conveying capacity, fast speed and easy operation, and can realize multi variety collinear shunt conveying.

Chain conveyor

Chain conveyor: the chain conveyor uses the chain as the traction and bearing body to transport materials. The chain can adopt ordinary sleeve roller conveyor chain or other special chains (such as stacking chain and speed doubling chain). The chain conveyor has large conveying capacity, mainly conveying pallets, large turnover boxes, etc. The conveying chain has various structural forms and has a variety of accessories, which is easy to realize stacking and conveying. It can be used as an assembly line or as the storage and transportation of materials.

Parameter of chain conveyor

Product | Chain conveyor |

Conveying mode | Double row chain |

Rated load | 1000kg |

Driving mode | Motor |

Conveying speed | 12m/min |

Power | 3 phase 380V 50HZ |

Machine material | Q235A |

Product features

The chain conveyor has the advantages of low price, simple structure, strong load capacity and convenient maintenance;

The above forms are standard model parameters, which can be customized according to the actual parameter needs of users.

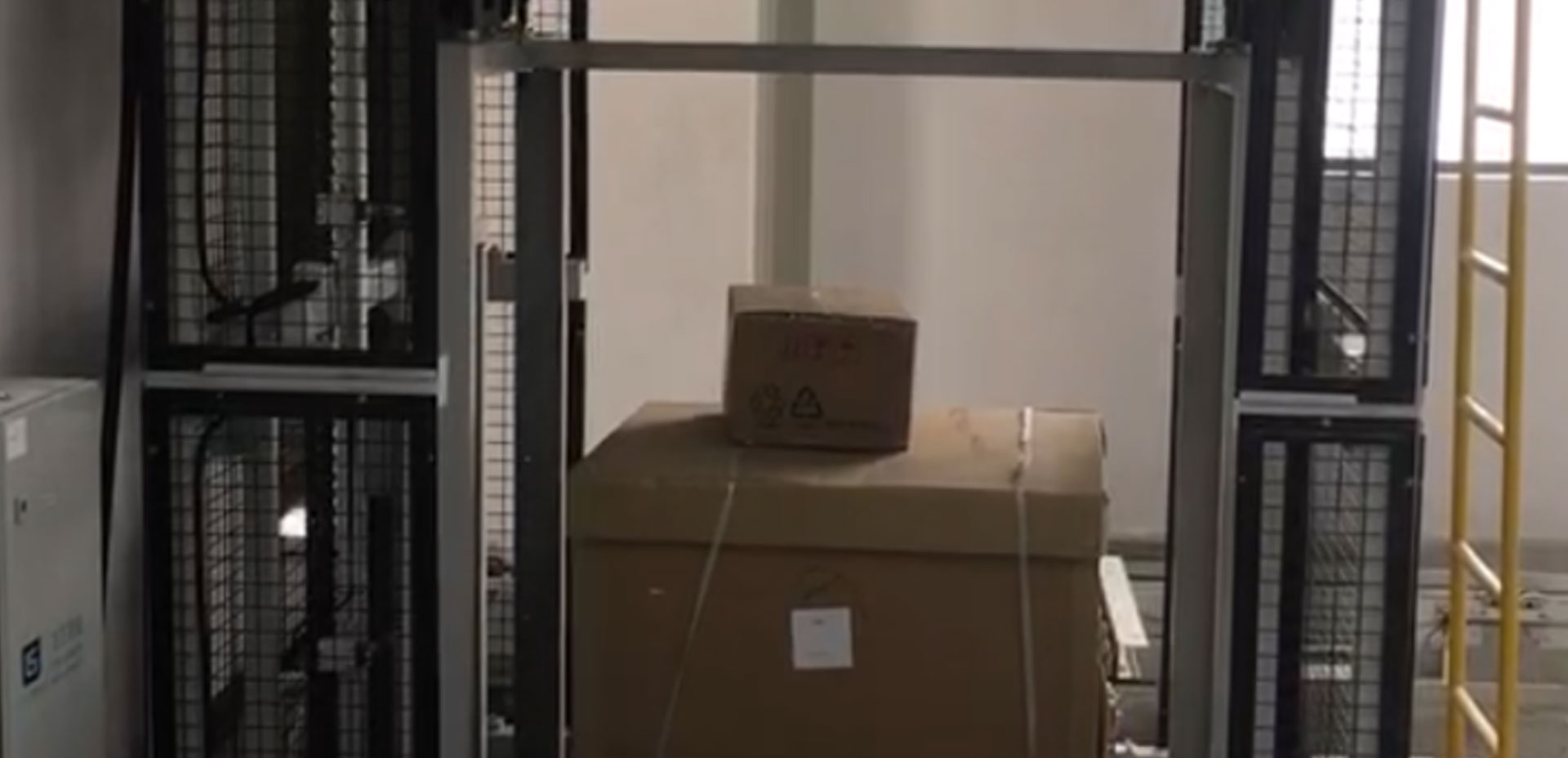

Vertical conveyor

Vertical conveyor: it is an important equipment to connect the conveyor systems between different floors into a larger continuous conveyor system. It can continuously transport materials vertically, so that continuous conveyors at different heights can keep uninterrupted material transportation.

The vertical conveyor has the advantages of long transportation distance, large transportation volume and continuous transportation. It also has reliable operation and is easy to realize automation and centralized control. It is an ideal transportation equipment to save floor area, equipment investment and improve transportation capacity.

Technical parameters of vertical conveyor

Product | Vertical conveyor |

Rated load | 1000kg |

Lifting mode | Chain |

Lifting speed | 30m/min |

Load moving mode | Roller |

Load moving speed | 12m/min |

Power | 3 phase 380V 50HZ |

Conveyor material | Q235A |

Product features

Modular combination, simple, convenient and fast assembly;

Simple structure, high reliability and convenient use and maintenance;

Small floor area for process layout;

The above forms are standard model parameters, which can be customized according to the actual parameter needs of users.

Applicable scenario

Vertical conveyor is a new type of vertical vibration conveying equipment, which is widely used in metallurgy, coal, building materials, grain, machinery, medicine, food and other industries. It is used for vertical lifting of powdery and granular materials, and the conveyor can also dry and cool the materials.

Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  中文

中文