In the past 2021, the volume of express delivery in China exceeded 100 billion for the first time, and the total number of parcels reached 108.5 billion, with an average of 77 parcels per person per year, and 6 parcels per month. This number is surprising. In the new year 2022, the State Post Bureau of China predicts that the business volume will continue to rise by 13%!

Not only the Chinese express delivery business has ushered in a peak period of development, but looking at the world, the logistics and express delivery industry has been developing rapidly due to the impact of the epidemic.

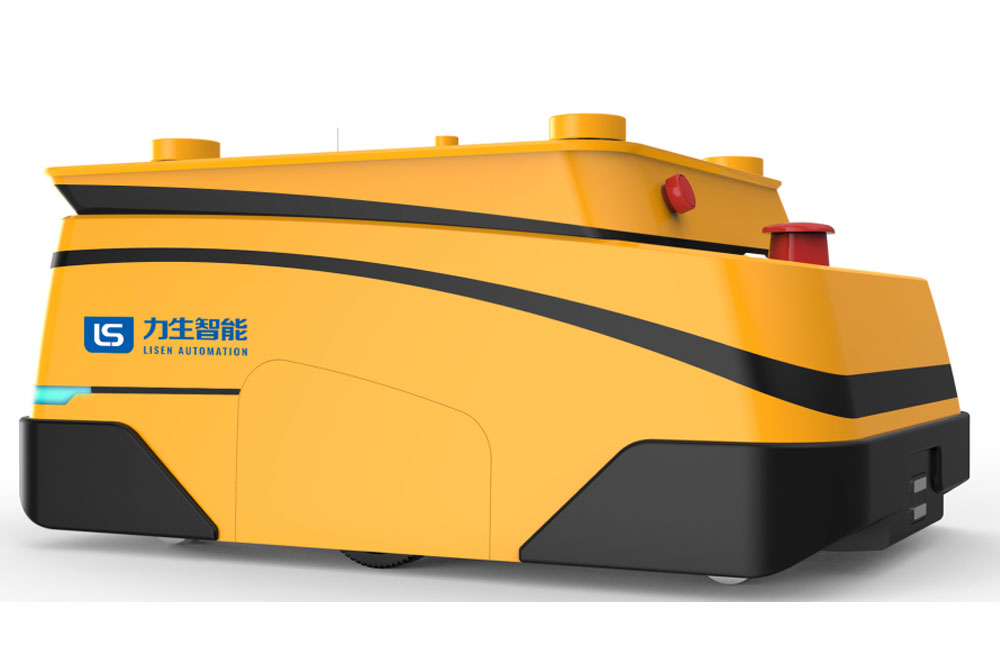

As a smart logistics solution provider

Lisen Automation creates a new [sorting black technology]

Automatic sorting equipment

Weighing, reading and sorting packages in one step

Small footprint, strong applicability, high cost performance

Once launched, it has become a hot sorting equipment at home and abroad

Has been successfully exported to Israel and Mexico

Korea, Poland, Italy and other countries

Trusted by customers around the world!

Automatic sorting equipment

Automatic sorting equipment is also called DWS system, all-in-one receiving and sending machine, all-in-one weighing and scanning code, etc. Automatic sorting equipment can be divided into four/thirteen/twenty-six/thirty-eight sorting grids and so on .

Frequent exports, why is it so "popular"?

As an indispensable part of front-end sorting, the traditional equipment is composed of an ordinary electronic scale + a scanning gun. It collects information manually, which is not only slow and inefficient, but also has a high error rate and labor costs. very high. Therefore, machine vision code reading came into being.

Lisen Automatic sorting equipment is equipped with a visual camera, which can automatically capture and identify cargo information and synchronize it to the control system.

According to the needs of the task, the goods are transported to the trolley and sorted to the designated compartment, and the sorting efficiency can reach 2000 pieces per hour.

There is a counting grating on the top of the sorting trolley, and a counting photoelectricity at the bottom of the grid. There is a full cargo lock button on the top of the grid. When the cargo is full, it will automatically give an early warning to realize the intelligent sorting management of the whole process.

Product advantages

1.High sorting efficiency, the sorting efficiency is 1200~1500pcs/h when weighing, and the sorting efficiency can reach 2000/h when not weighing;

2.Simple operation, extremely low error rate of 0.03%, reducing labor costs;

3. The product has obtained the EU CE certification, and the overall frame is made of European standard aluminum material, with reliable quality and exported overseas;

4. The bottom is supported by the caster cup assembly, which can be moved flexibly and conveniently;

5. Small footprint, suitable for distribution points with tight land use;High cost performance, affordable price and low investment cost.

In the ever-changing field of logistics, sometimes what customers need most is not necessarily the latest product, but the most suitable solution. Lisen Automatic sorting equipment provides multi-functional customization: the visual system can choose multi-faceted code reading, the appearance of the equipment can be adjusted according to the customer's corporate image color, and the number of grids can be extended according to on-site needs, and is committed to providing customers with optimal solutions. Meet diverse requirements and maximize value in different logistics application scenarios.

Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More Elaborate work, keepRead More

Elaborate work, keepRead More

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  中文

中文